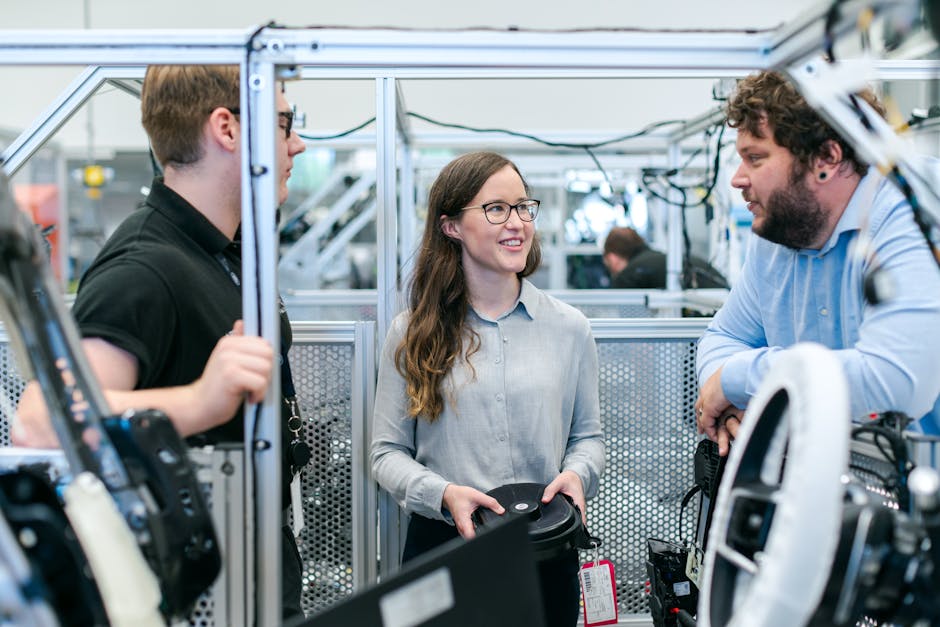

A journey through time exploring the evolution of industrial innovation reveals not just how products and processes have changed, but how human ingenuity has consistently overcome seemingly insurmountable challenges. Industrial innovation stands as the backbone of modern civilization, continuously reshaping our world through technological advances, manufacturing breakthroughs, and material science discoveries. From the steam-powered factories of the first Industrial Revolution to today’s smart manufacturing facilities, this transformation represents one of humanity’s most remarkable achievements.

The foundations of industrial progress

The industrial landscape we recognize today began taking shape in the late 18th century with the emergence of steam power. Before this pivotal moment, manufacturing relied primarily on manual labor, water wheels, and animal power. The introduction of steam engines revolutionized production capabilities, allowing factories to operate with unprecedented efficiency and scale. This marked the beginning of what historians now call the First Industrial Revolution, setting the stage for waves of innovation that would follow.

Early industrial pioneers faced significant material limitations. Sealing systems in these early machines, for instance, were primitive compared to modern solutions like kammprofile gaskets. These early sealing technologies often failed under pressure and temperature extremes, limiting operational efficiency and safety. The invention and refinement of more advanced sealing technologies would eventually become crucial to industrial advancement, though these developments would take decades to materialize.

The rise of precision engineering and specialized materials

The Second Industrial Revolution, spanning roughly from 1870 to 1914, saw the rise of electricity, petroleum, and steel as transformative forces in manufacturing. This period marked a shift toward more precise engineering and specialized industrial components. Engineers and inventors began developing more sophisticated approaches to machine design, focusing increasingly on efficiency, reliability, and safety.

During this era, manufacturers started recognizing the importance of specialized materials for specific applications. The primitive gaskets and seals of earlier decades gave way to more engineered solutions. However, extreme temperature applications remained problematic until the development of specialized materials like mica gasket material. Mica’s exceptional heat resistance and electrical insulation properties made it invaluable for high-temperature applications in the growing electrical and automotive industries. This natural mineral’s unique properties – able to withstand temperatures exceeding 1000°C while maintaining structural integrity – solved critical problems in industrial equipment that operated under extreme conditions.

A journey through time exploring the evolution of industrial innovation during this period reveals how interdisciplinary advances began accelerating technological progress. Developments in chemistry fed improvements in material science, which enabled mechanical engineering breakthroughs, creating a virtuous cycle of innovation that continues to this day. You can see this pattern repeating throughout industrial history – one field’s advances unlocking potential in seemingly unrelated domains.

The age of standardization and mass production

The early 20th century brought another revolutionary concept to industry: standardized mass production. Henry Ford’s assembly line techniques transformed manufacturing by emphasizing interchangeable parts, specialized labor roles, and continuous workflow. This approach demanded greater precision and reliability from industrial components.

Sealing technologies became increasingly sophisticated during this period. The development of kammprofile gaskets represented a significant advance over previous designs. These innovative gaskets featured a serrated metal core with a soft sealing material, providing superior sealing performance under varying conditions. Their design allowed for better load distribution and improved recovery, making them ideal for applications with fluctuating temperatures and pressures. As industrial processes grew more complex, these specialized components became critical to operational efficiency and safety.

The standardization movement extended beyond manufacturing techniques to encompass materials and components. Industry associations established specifications for materials like mica gasket material, ensuring consistent performance across applications and manufacturers. This standardization facilitated broader adoption of proven technologies and accelerated industrial development worldwide.

The digital transformation of industry

The latter half of the 20th century witnessed the beginning of industry’s digital transformation. Computers, initially massive machines with limited capabilities, gradually became smaller, more powerful, and ubiquitous throughout manufacturing environments. This digital revolution fundamentally changed how products were designed, produced, and maintained.

Computer-aided design (CAD) transformed how engineers developed industrial components, including specialized items like kammprofile gaskets. Design software allowed for more precise specifications, simulation testing, and optimization before physical production began. This significantly reduced development time while improving performance characteristics.

Material science continued advancing during this period, with synthetic alternatives supplementing natural materials like mica. However, for certain high-temperature, high-pressure applications, mica gasket material remained unmatched. The unique layered silicate structure of mica provides exceptional thermal stability and compression resistance that even advanced synthetic materials struggle to equal in certain applications.

Industry 4.0 and the connected future

Today, we stand at the threshold of what many call the Fourth Industrial Revolution or Industry 4.0. A journey through time exploring the evolution of industrial innovation brings us to a present defined by intelligent, connected systems incorporating sensors, data analytics, artificial intelligence, and robotics. These technologies are transforming manufacturing in ways early industrialists could scarcely imagine.

Modern industrial components now often feature embedded sensors that monitor performance and predict maintenance needs before failures occur. Even seemingly simple components like kammprofile gaskets can now be equipped with monitoring technology to detect pressure changes, leakage, or thermal variations. This predictive capability dramatically reduces downtime and improves operational safety across industries.

Material science continues to evolve, with researchers developing new composites and engineered materials with properties tailored to specific applications. Despite these advances, certain traditional materials remain relevant. Mica gasket material continues to play an important role in applications requiring extreme temperature resistance, demonstrating how time-tested solutions can complement cutting-edge technology.

The industrial innovation journey continues to accelerate, with advancements in one field enabling breakthroughs in others. Today’s industrial landscape reflects centuries of cumulative knowledge, experimentation, and problem-solving. As you look toward future developments, remember that each innovation builds upon a foundation laid by previous generations of inventors and engineers who faced and overcame the technological challenges of their time.